How Custom Digital Printing Reduces Waste

A tremendous advantage of digital over traditional printing is that custom digital printing reduces waste. How does it do that, exactly? Reduced waste manifests through smart, customized design, a flexible ordering process, and the elimination of non-usable excess inventory.

Today, we’re seeing consumers prioritize brands that walk the walk as well as talk the talk. To gain the attention and earn the loyalty of these customers, companies must make packaging and printing choices that actively reduce waste. Read on to learn more about how digital printing and custom packaging can help your company achieve greater sustainability and encourage deeper brand loyalty from your customers.

Custom Digital Printing Prevents Overproduction

Traditional printing techniques utilize presses that rely on print plates, and need significant calibration before a print run is ready. This set up produces quite a bit of waste just to get up and going. In addition, a company is likely to fold the costs of setting up into the price of the order. For this reason, many traditional printing jobs require a minimum order. If this minimum is higher than a company needs or can use before the packaging is obsolete, the packaging becomes waste.

Custom digital printing, on the other hand, uses no plates and requires far less calibration. Print quality is high-quality and consistent from first to last. The technology is flexible enough, as well, to adjust to customer need, rather than dictate it. A company may order as many units as it needs, and no more.

Digital printing allows a company to:

- Place and print orders in precise quantities

- Adjust orders to reflect changing needs

- Reduce waste with consistent print quality throughout the process

Custom Packaging Ends Void Fill

Void fill provides the necessary service of filling gaps and cushioning a product to prevent it from shifting during transit. Essential as it is to the protection of whatever is inside the box, a package that requires too much void fill is wasteful. Certainly, these days, more sustainable alternatives are available to replace non-recyclable packing peanuts and Styrofoam. While shredded paper and other fillers can sub for less environmentally friendly options, the best option is to avoid excessive void fill entirely.

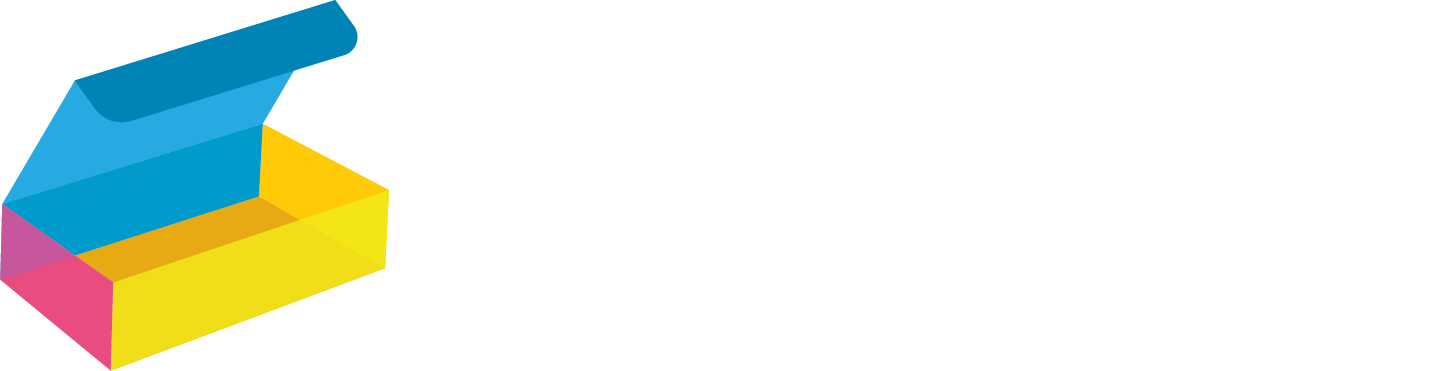

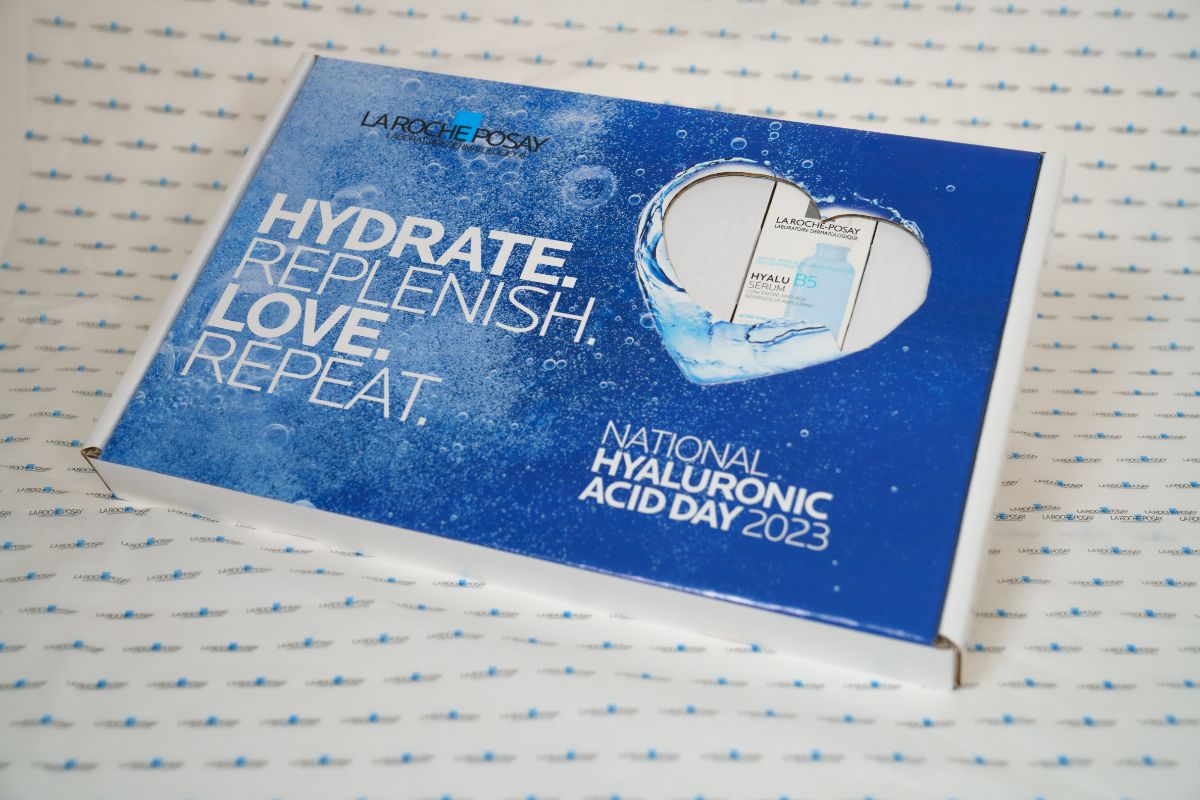

Custom packaging not only secures products for transport, it also reduces package size, which can potentially lower shipping costs. Snug as a bug in a rug, products ship economically, fully protected, and without adding egregiously to the landfill.

Customers Care About Waste as Much as You Do

Today’s digital-age consumers are not only savvy about what they consume, but also how they consume it and what happens when they’re done with it. In other words, waste matters. How much waste a product produces makes up part of the product profile for many consumers. Excessive or oversized packaging makes a bad impression and can negatively impact the way your brand is perceived. If style, excellent design, innovation, and attention to the environment are elements of your corporate culture, make certain your custom packaging and even mailer boxes reflects your values.

According to One Tribe, 73% of millennials and Gen-Z customers are willing to pay more for sustainably marketed products. This statistic doesn’t necessarily mean you need to spend more on your product packaging. The real takeaway is that smarter, more efficient packaging is more likely to draw and keep the attention of these important consumers.

Make the move to more sustainable and efficient packaging and marketing with BeBoxing’s custom digital printing services. We’d love to help you create the packaging and marketing materials that distinguish your products while reflecting your company’s dedication to waste reduction.